What’s rapid prototyping?

-First look prototype

-Sales and product demonstration

-Functional prototype testing

-Pre-production and market validation

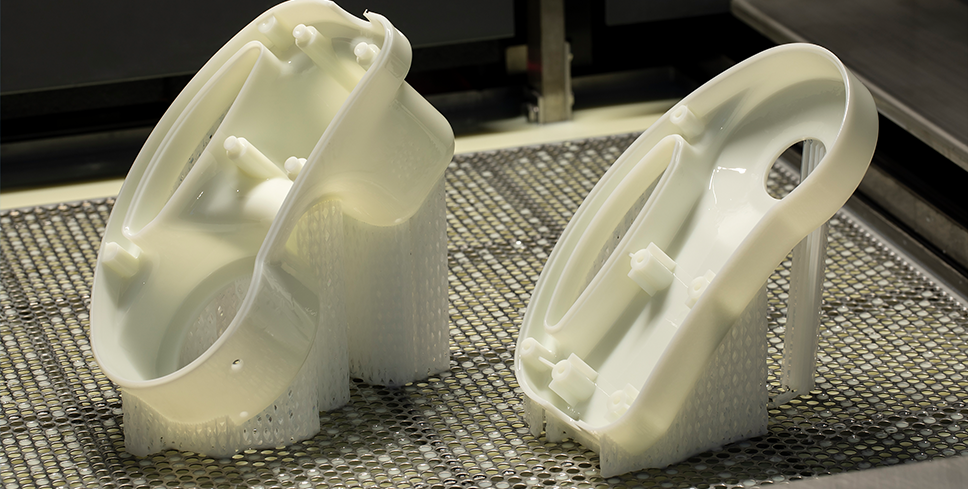

Main Types of Rapid Prototyping

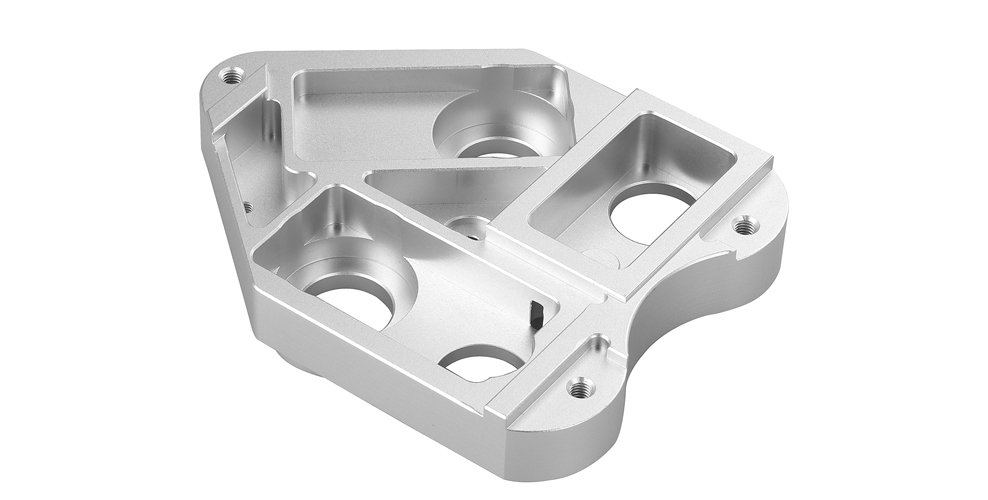

CNC machining

CNC Machining is a process used in the manufacturing sector that involves the use of computers to control machine tools. Tools that can be controlled in this manner include lathes, mills, routers and grinders. The CNC in CNC Machining stands for Computer Numerical Control. Metal materials as well as some hard plastic materials could be processed by CNC machining to a certain structure. The precision of CNC machining is very high so it is usually utilized for precision tools or objects that require high precision.Typical Materials: ABS, Aluminum alloy, stainless steel, carbon steel, copper and other metal materials

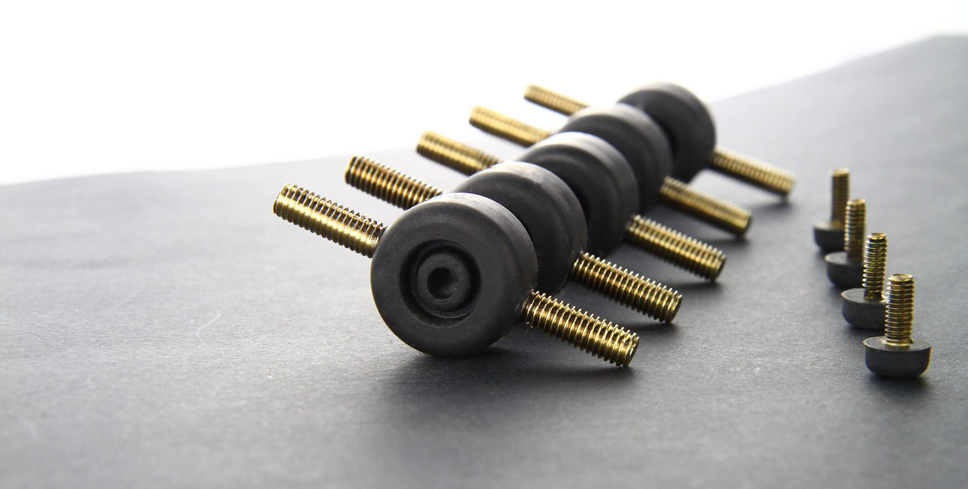

Rapid molding

Rapid molding is another way of prototyping. Somtimes, the material for prototyping is too soft and flexible. It is impossible to use either 3D printing or CNC machining. In such occasions, you might take consideration of rapid molding. Here rapid molding refers to fabricate a model by using rapid molds. There are various types of rapid molds, such as silicone rubber mold,vacuum casting mold,wax injection mold,plaster mold, aluminum alloy mold and so on. Compared with conventional molds, the advantages of rapid molds are low cost and fast production while the disadvantage is the poor life time of the molds.

Typical Materials: TPU rubber, silicone rubber

Typical materials for rapid prototyping

- Photopolymer

- Nylon

- PLA

- ABS

- Aluminum Alloy

- TPU Rubber

- Silicone Rubber

The product printed by photopolymer material has fine surface, good toughness, temperature resistance of 50 Celsius degrees, hardness of 79, white color after curing , tensile modulus is 2421-2525Mpa, tensile strength is 40-54Mpa, elongation rate after fracture is 7-10%, and the notched impact strength is 27-37J. Photopolymer is suitable for most hand-made parts.

3D printing nylon material has good impact resistance, high strength, good toughness, very high hardness, good dimensional stability, maximum heat resistance temperature of 140 ° C -160 ° C. The printed parts always have a powdery surface. The printed products are available in black and white.

Polylactic Acid, commonly known as PLA, is one of the most popular materials used in desktop 3D printing. It is the default filament of choice for most extrusion-based 3D printers because it can be printed at a low temperature and does not require a heated bed. PLA is a great first material to use as you are learning about 3D printing because it is easy to print, very inexpensive, and creates parts that can be used for a wide variety of applications. It is also one of the most environmentally friendly filaments on the market today.

ABS is a polymer obtained by copolymerization of three monomers of acrylonitrile A, butadiene B and styrene S, referred to as ABS. The appearance of ABS is opaque ivory pellets, non-toxic, odorless, low water absorption, density: 1.05 g / cm3. ABS materials have many properties such as low temperature resistance, impact resistance, low creep, excellent dimensional stability and ease of processing. ABS engineering plastics have a wide range of applications because of their high surface hardness and chemical resistance.

3D printed aluminum alloy material with good strength, lighter quality than stainless steel, yield point 17-220N, tensile strength 310-325Mpa, elastic modulus 75, thermal conductivity 150W/mk. Manufacture of lightweight part models for the automotive and aerospace industries.

The 8400 and 8400N are three-liquid type vacuum casting polyurethane rubbers having the following characteristics. By controlling the amount of the C group, the hardness can be arbitrarily adjusted within the range of from shore to 90.

Silicone rubber is a colorless or skin-colored oily liquid that becomes a soft elastic material after vulcanization. It can be used for a long time at -65 ° C to 200 ° C and maintains its soft elastic properties, electrical properties and chemical stability, water resistance It is resistant to ozone, weathering, non-corrosive, physiologically inert, non-toxic and tasteless, and has low line shrinkage.

Common Finish for Rapid Prototyping

Spray painting is a painting technique where a device sprays a coating (paint, ink, varnish, etc.) through the air onto a surface.

Vacuum plating includes several types, such as vacuum evaporation, sputtering and ion plating.They are all used to deposit various metal and non-metal films on the surface of plastic parts by distillation or sputtering under vacuum conditions. In this way, very thin surface coatings can be obtained. It is suitable for functional coatings for high-grade products, household appliances, cosmetic packaging and so on.

Screen printing is a printing technique whereby a mesh is used to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed. One color is printed at a time, so several screens can be used to produce a multicoloured image or design.

Laser engraving is the practice of using lasers to engrave an object. Laser marking, on the other hand, is a broader category of methods to leave marks on an object, which also includes color change due to chemical/molecular alteration, charring, foaming, melting, ablation, and more. The technique does not involve the use of inks, nor does it involve tool bits which contact the engraving surface and wear out, giving it an advantage over alternative engraving or marking technologies where inks or bit heads have to be replaced regularly.

Why Choose Zemaker’s Rapid Prototyping Services

Free DFM Feedbacks :Engineers of Zemaker will do the DFM analysis and let customers know DFM feedback ahead of orders

Save you cost :Cost-competitive rapid prototyping service with guaranteed quality

Save you time :Instant online quoting and order system

More Options :Wide range of materials and post-processing choices

1-to-1 Customer Service :Reliable technical guidance and better communication