Foxconn Technology Group

Since our company was founded in 1974, Foxconn’s vision has always been to provide technological products and solutions that bring convenience to people’s everyday lives. Today, Foxconn Technology Group is the most dependable partner for joint-design, joint-development, manufacturing, assembly and after-sales services to global Computer, Communication and Consumer-electronics ("3C") leaders, cooperating with world’s renowned companies like Apple, Huawei, Dell, LG, Blackberry and so on. Foxconn also sets up several research centers and testing laboratories for mechanism, material, electronics to conduct the services of science research and technology development worldwide. By the year 2018, Foxconn has over 30 factories and 25K employees worldwide and ranked 24th among the Fortune 500 companies. It will continue to seek for advance technologies to enhance people’s daily lives.

Foxconn Prototype Center

As everyone knows, prototype plays a very significant role in developing a new product from idea to mass production. It will reveal some design problems and let the designer know how to improve the design before the production. Welcome to Foxconn prototype center, your reliable manufacturing partner, let’s accelerate the development within limited lead time. Here we make money for you via saving your time.

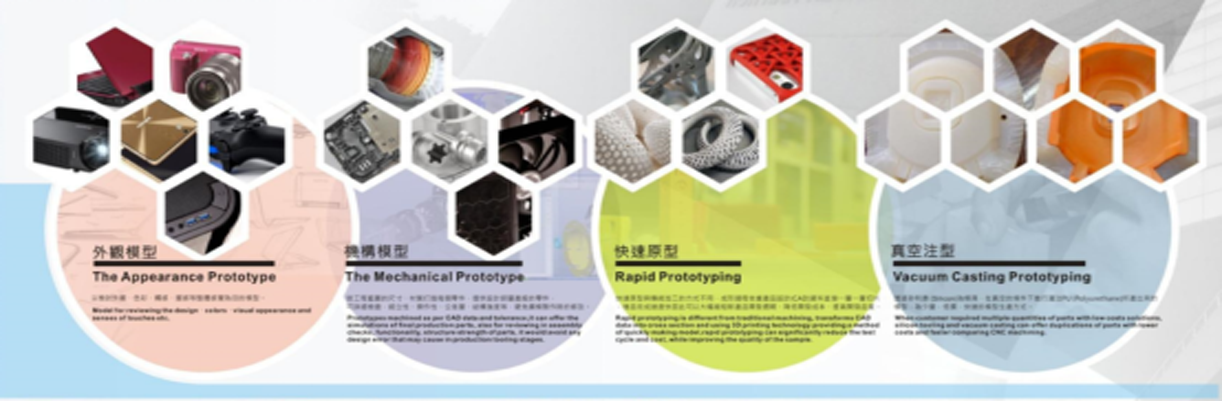

Application

*The Apperance Prototype

Model for reviewing the design, colors, visual appearance and sense of touches etc.

*The Mechanical Prototype

Machined as per drawing data and tolerance. It can offer the simulations of final product parts and help check the assembly, functionality, structure strength of parts. It would avoid design error that may occur in the production tooling stage.

*Rapid Prototyping

It is different from traditional machining, transforming drawing data into cross section and using 3D printing technology to create a quick model. Rapid prototyping can significantly reduce the test cycle and cost, while improving the quality of the sample.

*Vacuum casting prototyping

When customer required multiple quantities of parts with low cost solution, silicon tooling and vacuum casting can be an option, which could offer duplication of parts with lower costs and faster speed compared with CNC machining.

HERE’RE SOME OF OUR REPRESENTATIVE CUSTOMERS: