What’s molding?

Main Types of Mold

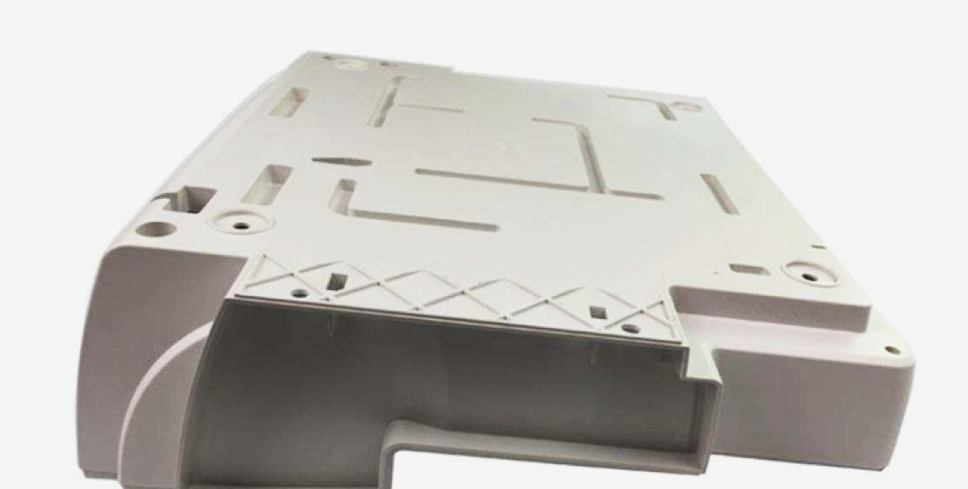

Injection Molding

The injection Process Methods refers to a process in which molten raw materials are injected into a mold cavity by pressurization, and then a certain shape of the product is produced by cooling, detachment, and the like. The accuracy of the products produced by injection mold can be high, with a dimensional accuracy of ± 0.02mm at highest. Because of the low cost of injection molding, it is widely used in electronics, electrical appliances, auto parts, kitchen supplies, medical supplies, cosmetics, sporting goods, etc.

Die-casting Molding

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

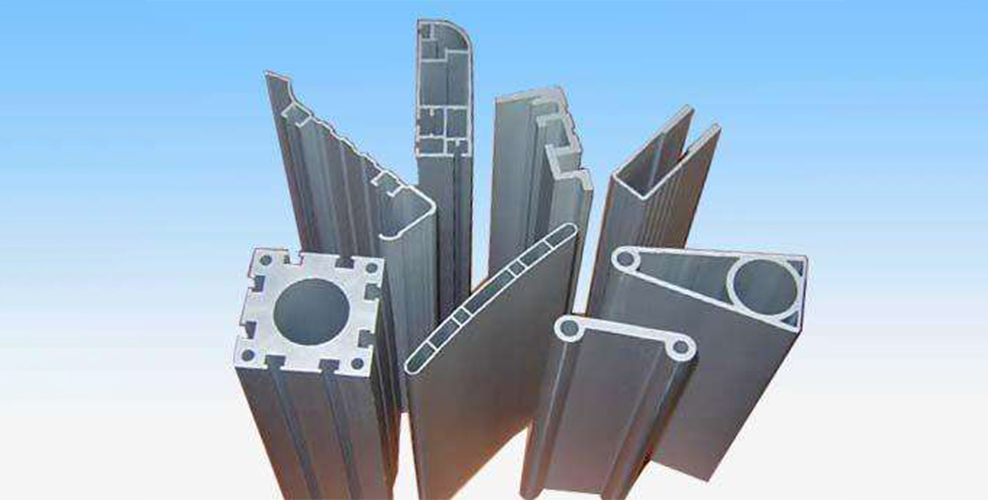

Extrusion Molding

Extrusion is a manufacturing process used to make pipes, hoses, drinking straws, curtain tracks, rods, and fibre. The granules melt into a liquid which is forced through a die, forming a long 'tube like' shape.

Compression Molding

Compression Molding is a method of moulding in which the moulding material, generally preheated, is first placed in an open, heated mould cavity. The mould is closed with a top force or plug member, pressure is applied to force the material into contact with all mould areas, while heat and pressure are maintained until the moulding material has cured. The process employs thermosetting resins in a partially cured stage, either in the form of granules, putty-like masses, or preforms.

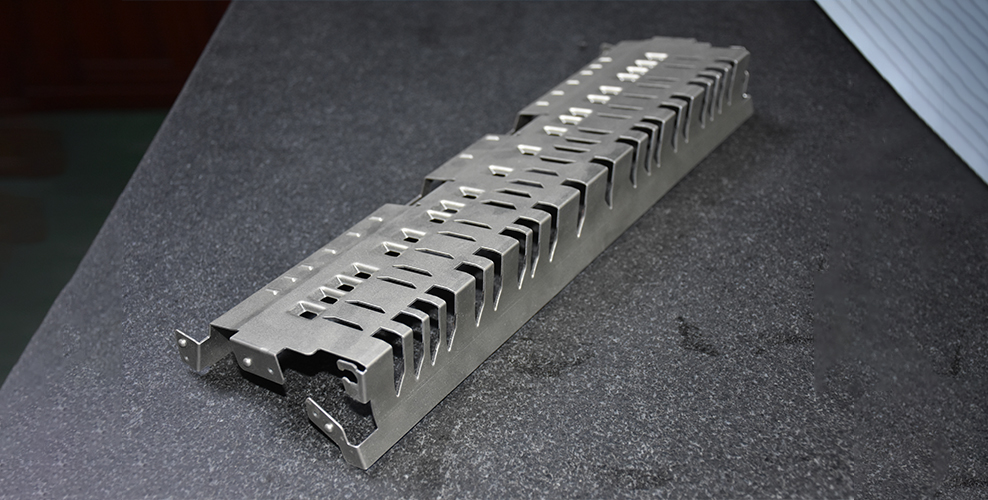

Sheet Metal Molding

Although some sheet metal moldings are used for metal sheets over 8 or even 10mm ,but usually we call a ”sheet”metal when its thickness is below 6mm. Sheets metal molding is probably the most diversified molding method,it bends,stamps,cuts,rolls,perforates and rivets metal sheets.

Why Choose Zemaker’s Molding Services

Free DFM Feedbacks :Engineers of Zemaker will do the DFM analysis and let customers know DFM feedback ahead of orders

Save you cost :Cost-competitive molding service with guaranteed quality

Save you time :Find the most suitable factory based on Zemaker’s internal system data

More Options :Wide range of molding and post-processing choices

1-to-1 Customer Service :Reliable technical guidance and better communication