Engineers Specialized in Various Fields

Zemaker has more than 100 engineers specialized in various fields to support your projects. We got engineers worked in molding companies over 10 years, designed hundreds of various mold and supervised mold-making. We got engineers had their own cnc shops before knowing everything about how cnc suppliers think. We got engineers worked in giant international companies as purchasing engineering, they have tones of experiences in how to reach international quality standard. We also have engineers worked over 10 years as project manager followed projects from an idea to final production. And we also work with hundreds of engineers in Foxconn and can borrow their expertise in various fields.

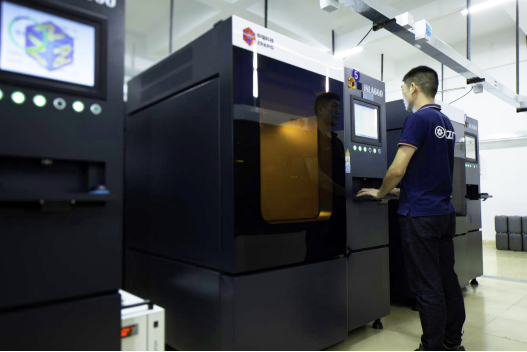

Rapid Prototyping Engineers

There are more than 30 engineers in Zemaker specialized in rapid prototyping projects. Ever since the establishment of the company, they have faced many different types of prototyping projects. The total quantity of the prototyping parts produced by Zemaker has exceeded 1 million. Unlike other engineers, prototyping engineers are more familiar with some special production skills, like 3D printing, silicone rubber molding, various means of vacuum molding and surface treatment. They know what is the best way to make the most beautiful prototypes and the most cost-effective methods.

CNC Machining Experts

The difference between a CNC machining engineer and an expert CNC machining engineer is quite obvious. An expert CNC machining engineer is able to judge the 3D models in very a short time and make programs shortly. CNC machining experts are familiar with the properties of the various materials. And more importantly, they have their own techniques to deal with some parts that seems impossible to be produced by normal CNC machining engineers. In Zemaker, there are more than 50 CNC machining experts, who could make the precise parts for you at a favorable cost.

Mold Design Engineers

Molding is a complicated way of manufacturing large volume of products. Generally speaking, there are five commonly used molds, namely injection mold, stamping mold, die-casting mold, extrusion mold, blowing mold. While doing the mold design, engineers have to consider many factors :molding materials, surface requirements, mold lifetime, product structure, mold structure, mold heat radiation and etc. Zemaker’s engineers who specialized in mold design have more than 15 years relevant experience. Because these engineers have got access to more than 200 mold projects per year, they also know well about the capability of the manufacturing partners. They know what would be the potential risks for massive production and could take relevant measures to avoid these in advance.

Sheet Metal Engineers

Zemaker’s engineers who specialized in sheet metal have worked in this field for more than 10 years. They are so familiar with all the manufacturing processes that sheet metal needs and have taken part in many US and European projects before. Thus they are familiar with the standard requirements for application in 5G industry, electronic appliance, automation machines. Surely, with these engineers help, you will feel it’s very easy to communicate with staff from Zemaker about the technical key points.

Industries Zemaker Has Been Engaged In

The industries Zemaker has been engaged in are automobile industry, medical industry, intelligent hardware, automation equipment industry, robotics industry, household appliances industry, energy equipment industry, research institution projects, supplying various kinds of customized metal or plastic parts at all quantities.

.png)