What’s CNC machining?

Main Types for CNC Machining

CNC Milling

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. The milling process requires a milling machine, workpiece, fixture, and cutter. The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached to a platform inside the milling machine. The cutter is a cutting tool with sharp teeth that is also secured in the milling machine and rotates at high speeds. By feeding the workpiece into the rotating cutter, material is cut away from this workpiece in the form of small chips to create the desired shape.

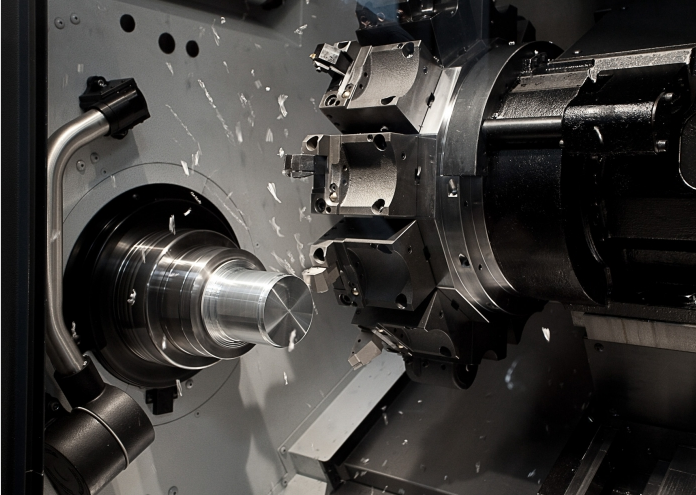

CNC Turning

Turning is a form of machining, a material removal process, which is used to create rotational parts by cutting away unwanted material. The turning process requires a turning machine or lathe, workpiece, fixture, and cutting tool. The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached to the turning machine, and allowed to rotate at high speeds. The cutter is typically a single-point cutting tool that is also secured in the machine, although some operations make use of multi-point tools. The cutting tool feeds into the rotating workpiece and cuts away material in the form of small chips to create the desired shape.

Typical materials for CNC Machining

- ABS

- Aluminum Alloy

- Brass

- Copper

- POM

- Nylon

- Steel

ABS is a polymer obtained by copolymerization of three monomers of acrylonitrile A, butadiene B and styrene S, referred to as ABS. The appearance of ABS is opaque ivory pellets, non-toxic, odorless, low water absorption, density: 1.05 g / cm3. ABS materials have many properties such as low temperature resistance, impact resistance, low creep, excellent dimensional stability and ease of processing. ABS engineering plastics have a wide range of applications because of their high surface hardness and chemical resistance.

Aluminum Alloy are alloys in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.

Brass is an alloy of copper and zinc, in proportions which can be varied to achieve varying mechanical and electrical properties. It is a substitutional alloy: atoms of the two constituents may replace each other within the same crystal structure.

Copper is a relatively pure copper. It is generally considered to be pure copper. It has good electrical conductivity and plasticity, but its strength and hardness are poor. Copper has excellent thermal conductivity, ductility and corrosion resistance. Copper has good weldability and can be processed into various semi-finished and finished products by cold and thermoplastic processing. It is mainly used for making electrical equipment such as generators, busbars, cables, switchgear, transformers, etc., and heat exchangers such as heat exchangers, pipes, and flat-plate collectors for solar heating devices.

POM raw material, one of synthetic resin, also known as polyacetal resin, steel and steel. POM is a crystalline plastic with a density of 1.42g/cm3. It is a white or black plastic granule. It has excellent properties such as fatigue resistance, creep resistance, abrasion resistance, heat resistance and impact resistance, and its friction coefficient is small. Good lubricity, POM is not easy to absorb moisture.

Nylon is a generic designation for a family of synthetic polymers, based on aliphatic or semi-aromatic polyamides. Nylon is a thermoplastic silky material that can be melt-processed into fibers, films, or shapes. It is made of repeating units linked by amide links similar to the peptide bonds in proteins. Nylon polymers can be mixed with a wide variety of additives to achieve many different property variations. Nylon polymers have found significant commercial applications in fabric and fibers (apparel, flooring and rubber reinforcement), in shapes (molded parts for cars, electrical equipment, etc.), and in films (mostly for food packaging).

Steel is an alloy of iron and carbon, and sometimes other elements. Because of its high tensile strength and low cost, it is a major component used in buildings, infrastructure, tools, ships, automobiles, machines, appliances and so on.

Common Finish For CNC Machining

Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodizing increases resistance to corrosion and wear, and provides better adhesion for paint primers and glues than bare metal does.

No further surface treatment after the part is milled from a processing machine. If the products don’t need special surface protection or decoration, it can be fine and cost effective to choose none surface finishing requirement.

Spray painting is a painting technique where a device sprays a coating (paint, ink, varnish, etc.) through the air onto a surface.

Sandblasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants.

Why Choose Zemaker’s CNC Machining Services

High Accuracy :Customers on Zemaker could get access to CNC machining service up to 0.002mm precision provided by Foxconn without a MOQ

Free DFM Feedbacks :Engineers of Zemaker will do the DFM analysis and let customers know DFM feedback ahead of orders

Save you cost :Cost-competitive CNC machining service with guaranteed quality

Save you time : Instant online quoting and order system

More Options :Wide range of materials and post-processing choices

1-to-1 Customer Service :Reliable technical guidance and better communication