Basic Things You Need to Know about 3D printing

What is 3D Printing?

3D printing stands for various processes that make liquid or powder material joined or solidified layer by layer through a 3D printer or 3D printing machines. This manufacturing technology is also know as Additive Manufacturing and is now widely used for rapid prototyping.

Key Points: 3D modeling, digital slices, manufactured layer by layer

Main 3D Printing Categories

Based on different processing methods,

3D printing can be divided into the following types:

Fused deposition modeling(FDM)

Electron Beam Freeform Fabrication (EBF)

Direct metal laser sintering (DMLS)

Electron beam melting (EBM)

Selective laser melting(SLM)

Selective heat sintering (SHS)

Selective laser sintering (SLS)

Plaster-based 3D printing (PP)

Laminated object manufacturing (LOM)

Stereolithography (SLA)

Digital-Light Processing (DLP)

PolyJet & MutiJet

Thermoplastics, Eutectic System Metals, Edible Materials

Almost all the metal material

Almost all the alloy

Titanium alloy

Titanium Alloy, Cobalt-Chromium Alloy, Stainless Steel, Aluminum

Thermoplastic powder

Thermoplastics, Metal Powder, Ceramic Powder

Plaster

Paper, Metal Film, Plastic Film

Desktop 3D printer of Stratasys

/

/

/

3D Systems,EOS,Renishaw

/

Farsoon

3D Systems

Hu Bin

Advantages of 3D Printing

Cost-effective for rapid prototyping

Unlike CNC machining or molding, there will be much less material waste and tooling work. Thus 3D printing will save your cost for rapid prototyping.

Very short lead time

The speed of 3D printing is shorter than other traditional manufacturing technology. No time needed for CNC programming or mold design. 3D printed parts could be shipped out within 24 hours.

Complicate design for each part at the same time

There are some complicate designs. Both CNC machining and molding cannot deal with but 3D printing can do. You can print many parts together at the same time.

Limitations of 3D Printing

Limited Accuracy

Currently, due to the technology limitation, the accuracy of the top industrial 3D printing machine is ±0.01mm. However, the most common accuracy of a 3D printing service is among±0.1~0.2mm. In some desktop 3D printing occasion, the accuracy may even reach ±0.5mm.

Less cost-competitive for massive production

Compared with molding manufacturing, 3D printing is less cost-competitive. Molding manufacturing can make the cost of product to an extreme low cost.

Physical Property Change

Because 3D printed parts are built layer by layer, the strength of 3D printed parts will be less then bulk material. Thus it is not advised to use plastic 3D printed parts as the final functional parts.

When to Use 3D Printing?

Many people know about 3D printing but they don’t know when they should use it. Here’re some occasions we might suggest:

-

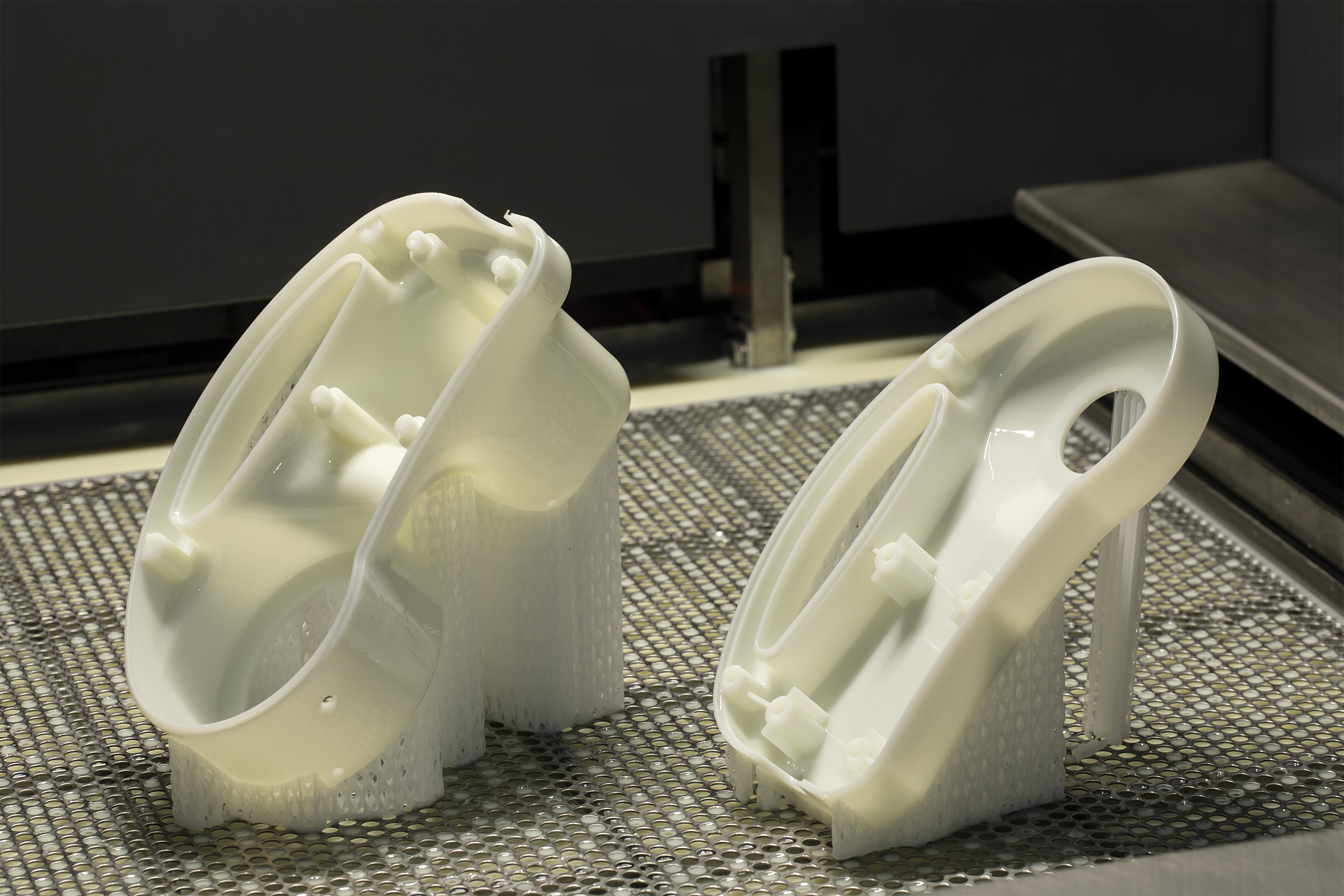

Appearance Check

When you finish the 3D model for a new product, you don’t know what it would look like as a physical object. It would be suggested if you could print your design out to check its appearance. Sometimes, you could improve your design a lot after you get a real one in your hands.

-

Functional Testing

The function is the key to a new product. Will the new design work properly? You should make a prototype to find the results. 3D printing can be a cost-effective way at the early stage of your project.

-

Assembly Testing

In some cases, the parts meet your requirements when they are separate, but after you assemble them together, they no longer work in a collaborative way. So assembly testing is a significant process to verify your design before large volume production. 3D printed samples will help you find out these initial assembly problems.

-

Marketing

With 3D printing, marketing and advertising agencies can have all the benefits of the product “visibly,” even if it doesn’t yet exist. In art exhibitions, stores, and museums, 3D printed samples tell people what you do/sell/exhibit directly at sight. Moreover, some complicated structures could only be produced by 3D printing.

-

Manufacture

With 3D printing, marketing and advertising agencies can have all the benefits of the product “visibly,” even if it doesn’t yet exist. In art exhibitions, stores, and museums, 3D printed samples tell people what you do/sell/exhibit directly at sight. Moreover, some complicated structures could only be produced by 3D printing.

-

Medical Care

It’s no longer a new thing that 3D printing can also be used for medical care. The customization of the 3D printing made it possible for dentists to prepare a customized artificial tooth.

What Industries Are Using 3D Printing Services?

Today, many companies and individuals are utilizing 3D printing technology to facilitate the work in their own fields. Just to name a few industries as samples:

- Mechanical Engineering

- Industrial Design

- Health Sector

- Jewelry

- Aircraft Industry

- Space Industry

- Individual Tech Geeks

What to Consider When Using 3D Printing Service?

CNC Machining for Metal Parts

This is the first thing you need to consider. 3D printing can be a good way to check looks-like samples. However, if your final product requires high precision or collaboration with other parts, please make works-like prototypes in the same way that you will do for small or large volume production.

Choose the right materials

This depends on where you use the printed parts and the purpose of making a prototype. Resin is the most widely used material for general purpose. Nylon and nylon plus glass fiber are more rigid. Metal printed parts are usually utilized for jewelry or aerospace parts.

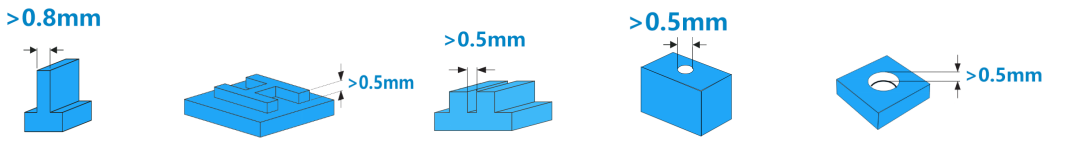

Make sure your design conform to the 3D printing limitations

Due to the limitation of 3D printing technology, please make sure that your design conforms to the following normal dimensional limits of a 3D printing service (for SLA 3D printing).

Find the right supplier

The last but not least thing, find a professional 3D printing service provider. An experienced 3D printing supplier can check your design and let you know the potential printing problems and guide you to make relevant design changes.

Why Choose Zemaker’s 3D Printing Services?

Save you cost:Cost-competitive printing service with guaranteed quality

Save you time:Instant online quoting and order system

More Options:Wide range of materials and post-processing choices

1-to-1 Customer Service: Reliable technical guidance and better communication